LED featured environmental friendly,energy saving and long life span.So it wildly used for lighting industry.The most common LED lighting housing are made via die casting.The die casting have advantage over cost,production efficiency and tight tolerance.

As for die casting,we normally use aluminum ADC12.It is very cost effective and average properties aluminum alloy.The density of ADC12 is only about 2.7g/cm³,so there will be no problem for the weight of street LED light housing,sometimes,it is really big.By die casting,the product need less secondary machining because most of structure can be done via toolings,which save huge cost for buyers.Please contact us if you have any inquiries about die casting.

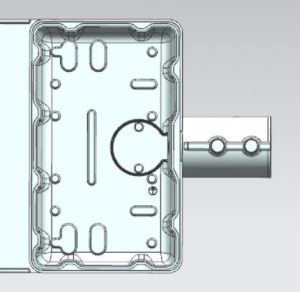

When it comes to the design of LED light housing,the wall thickness is main factor which required to take into consideration.Uniform wall thickness is first of first and can avoid shrinkage porosity and crack and deformation.Moreover,uniform wall thickness can extend life span of tooling.Normally,the wall thickness is less than 6mm.As the wall thickness increasing,the physical properties become lower.

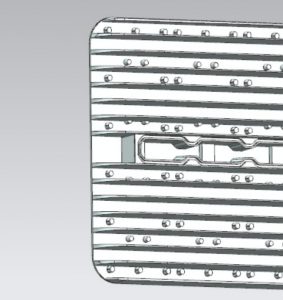

Ribs are aim to reinforce strength of die casting parts and avoid shrinkage porosity caused by thick wal.Meanwhile,ribs can make molten alloy flow inside cavity smoothly and improve die casting quality.Normally,the height of ribs can not be more than 15 times of wall thickness.The thickness of ribs less than 1.5 times of wall thickness.Draft need to be as small as possible in order to save material.In some special occasion,the draft can be 0.5°.

Radius is useful for molten alloy flow smoothly and good for ventilation and formation of castings.The crack of casting and toolings can be avoided via proper radius.Moreover,radius can improve tooling life span.

The narrow and deep cavity should be avoid.To make narrow and deep cavity,there will be narrow and high boss on the tooling,which is very easy to broken and bend.

To make good quality final product,precision machining is necessary.The precision of die casting is average and it will need precision machining sometimes.For contact surface,the precision machining is required most time.

For most of LED lighting housing,corrosion resistance is very important.Normally,we provide ISO12944 C5 corrosion resistance.