In addition to HPDC, we provide low pressure die casting(LPDC) as well. The process can be simplified as that molten alloy is forced into cavities via low speed and pressure.

In low pressure die casting, the die is filled with metal from a pressurised furnace, with pressures typically around 1 bar. The holding furnace is positioned in the lower part of the vertical die casting machine, with the molten metal injected upwards directly into the bottom of the mould. The pressure holds the metal in the die until it solidifies.

In weiheng, we provide full range of service related to low pressure die casting. From most common A356 to expensive as A201, we will suggest proper aluminum alloy according to design and usage of castings.

Our modern and advanced equipment can ensure tooling quality and maximize tooling life span. Up to hundreds of kilograms castings is ok for us to produce by LPDC. Our core making machine can slove the problem that the casting has cavities and concaves.

Our capabilities of precison machining and surface treatment can meet customers requirement.

Pros of low pressure die casting

- 1. Very good strength values

- 2. Complex geometries possible as sand cores can be used

- 3. Higher material utilisation

- 4. High dimensional accuracy

- 5. Less complicated machine

- 6. Suitable for heat treatment

- 7. Low porosity

Cons of low pressure die casting

- 1. Relatively big investment for tooling

- 2. Not suitable for thin wall parts

- 3. low production rate than HPDC

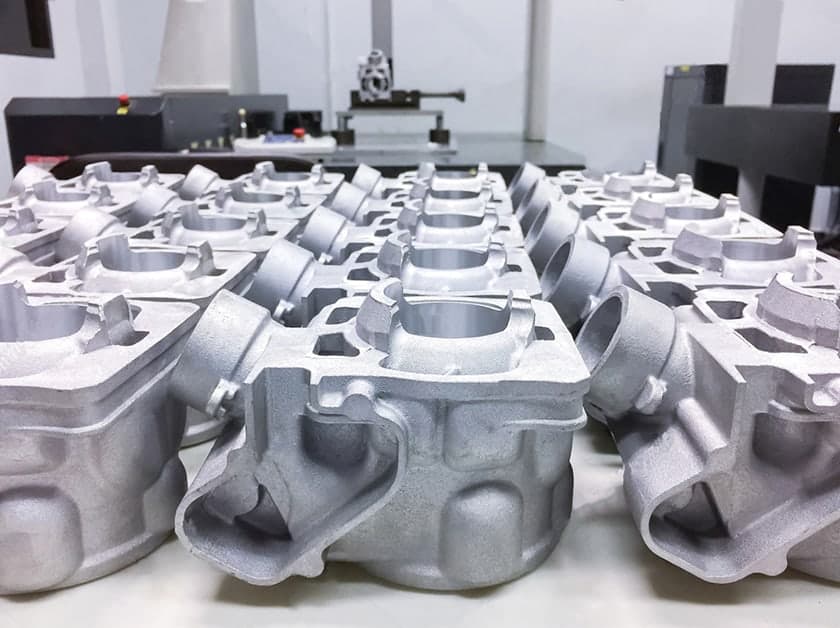

Low pressure die casting is mainly used to produce aluminum parts, such as automobile hub cylinder block, cylinder head, piston,impeller, wind guide wheel and other castings with complex shape and high-quality requirements.

Our featured products ↓

LOW PRESSURE DIE CASTING

High yield, dimensional accuracy casting method. Nice mechanical and metallurgical properties of the castings. Low Porosity.