Multitasking lathes can significantly improve production yield for die casting parts in several ways:

- Reduced setup time: Multitasking lathes integrate various machining processes into one machine, eliminating the need to transfer parts between multiple machines. This reduces setup time and minimizes the potential for errors during part handling, leading to faster production cycles and increased yield.

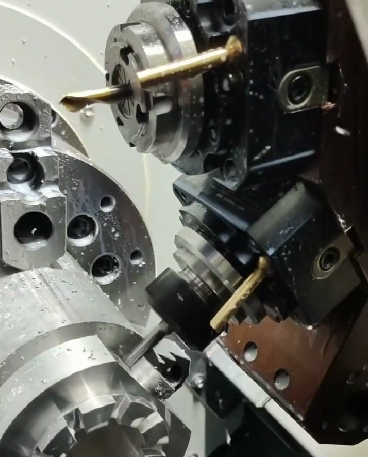

- Streamlined workflow: By performing multiple operations such as turning, milling, drilling, and tapping in a single setup, multitasking lathes streamline the manufacturing process. This reduces idle time between operations and ensures continuous production flow, thereby maximizing efficiency and overall yield.

- Improved precision and accuracy: Multitasking lathes are equipped with advanced CNC controls and tooling systems that enable high precision machining. With the ability to perform multiple operations in a single setup, these machines can maintain tight tolerances and consistent quality across all features of the die casting parts, resulting in higher yield rates by reducing scrap and rework.

- Flexibility in part design and complexity: Multitasking lathes offer versatility in machining capabilities, allowing manufacturers to produce a wide range of die casting parts with varying geometries and complexities. This flexibility enables manufacturers to meet diverse customer requirements and adapt to changing market demands, ultimately enhancing production yield by accommodating a broader range of part designs.

- Reduced lead times: With the ability to complete multiple operations in a single setup, multitasking lathes can significantly reduce the overall production lead times for die casting parts. This enables manufacturers to respond more quickly to customer orders and market demands, improving overall throughput and yield.

- Minimized material waste: Multitasking lathes optimize material usage by reducing scrap and minimizing the need for secondary machining operations. By efficiently machining parts from raw material stock, these machines help minimize material waste and maximize the utilization of resources, ultimately improving production yield and cost-effectiveness.

Overall, the integration of multitasking lathes in die casting part manufacturing processes can lead to higher productivity, improved quality, and increased profitability through enhanced production yield and efficiency.