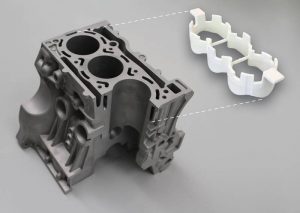

With development of automobile industry,more and more aluminum die casting parts are used in building automobile.The hollow die casting parts can improve strength of structure and lower weight.Vacuum die casting is mostly used in automobile industry and can get thin wall in 2.5 mm with complex geometry.The ribs and holes on the side can be produced by tooling with sliders while the hollow parts can not be made by such way.However,the complex hollow parts can be made by using salt core during die casting and salt core can be removed by water.Weiheng Die Casting Use Salt Core Techonolgy over years

Water dissolved salt core means that the core made by water dissolved salt and it will be removed by high pressure water after die casting.In compare with sand core used in low pressure or sand casting,

Salt core featured in high strength,good castings surface finishing,less vapor,easy cleaning,no damage to parts and environmental friendly.In addition,salt can be recycled.Therefore,more and more water dissolved salt core will be used in automobile industry.

During high pressure die casting,core of tooling need to resist temperature from 680 to 720℃ and impact of melted alloy at speed in 20-50m/s. Therefore,water dissolved salt has to be high strength and meet requirement of high pressure and low pressure die casting.Yield rate of salt core need to match high pressure die casting.Tensile strength of salt core need to be more than 20 MPa.Salt core also need to have good dissolution and easy to clean up and no reaction to alloy and recycle usage.

In consideration of yield rate of high pressure die casting and forming of sale core,pouring method is main way to make salt core.The solidification time of salt core is longer than alloy during die casting,which badly affect production efficiency.Therefore,the strength of salt and reduction of crack need to be improved.It is necessary to create evaluation system of salt core in order to provide standard of salt core making and simulation of filling and solidification.It is useful to find potential risk of crack during die casting and provide technical support for tooling design and making.

If any inquiry about die casting,please send email to info@prodiecasting.com

We are interested of your sand cores. Can you give me more information for them?

Dear :

We are interested in implementing and developing salt core for die casting (water pumps).