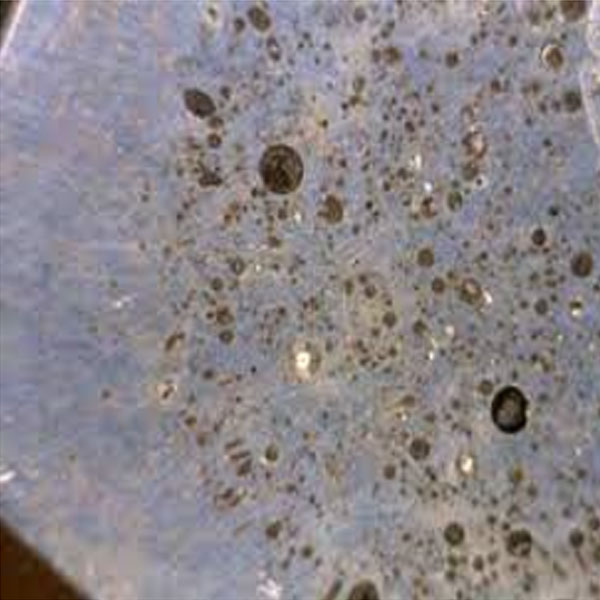

Porosity caused by poor refine of material.Weiheng Die Casting is professional to control porosity.

The temperature of melted aluminum alloy normally is 610-660℃ in die casting.At this temperature,there is lots of gas(mainly hydrogen) in melted alloy.At 660℃,hydrogen is 0.69cm3/100g in melted aluminum alloy,while it is 0.036m3/100g in solid aluminum alloy.Therefore,there is lots of hydrogen bubble contained inside aluminum die castings.

The refine of melted aluminum alloy is to reduce gas in melted aluminum alloy.The less gas contained in melted aluminum alloy,the less of porosity in final aluminum die castings.Therefore,refine of melted aluminum alloy is important process in die casting.Refine agent will be react with melted aluminum alloy at 660℃.The reaction not very big and there will be bubble come out of melted aluminum alloy and hydrogen come out together with these bubbles.It is not recommend to react for quite long time.Better to control reaction within 6-8 minutes.

Porosity caused by poor ventilation

Porosity normally caused by poor tooling ventilation design.The air can not get out of tooling,which caused some porosity inside castings.Porosity caused by air is quite different from the one caused by hydrogen.The wall of the pore caused by air is white while pore caused by hydrogen is grey.

Porosity caused by wrong die casting machine setting

The air inside cavity can not push out because the injection speed is far too fast.Therefore,the air left over will trap and form a large pore inside castings.Normally,such pore exist underneath of surface of casting.

Shrinkage porosity

The aluminum alloy is same as other material and has shrinkage during cooling down.The higher the temperature is,the bigger the shrinkage.Most of shrinkage porosity exist around pore caused by hydrogen.For this problem,it need to lower the temperature of melted aluminum alloy as much as possible in order to reduce shrinkage of casting.

Porosity caused by ununiform wall thickness.

There are normally porosity in the castings center where the area become solid finally.Therefore,it is necessary to diminish ununiform wall thickness and add slider and water cooling system in toolings.

If any inquiry about die casting,please send email to info@prodiecasting.com