3D printing is such a magical technology that it extends into almost every sector relating to manufacturing,not to mention casting production.In this paper,the past,present and future of 3D printing in the foundry sector are profoundly reviewed.3D printing has the potential to supplement or partially replace the casting method.Today,some castings can be directly printed by metal powders,for example,titanium alloys,nickel alloys printing the was pattern,ceramic shell,sand core,sand mould,etc.Most importantly,3D printing is not just a patterns,cores,moulds and shells in casting production.The solid structure of castings and moulds will be redesigned in future into truss or spatially open and skeleton structures.This kind of revolution is just sprouting,but it will bring unimaginable impact on manufacturing including casting production.Nobody doubts the potential of 3D printing technologies in manufacturing,but they do have limitations and drawbacks.Weiheng Die Casting Provide 3D printing service for prototyping.

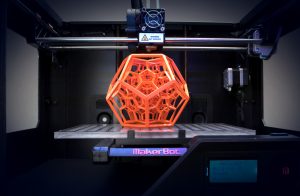

3D printing has become such a hot research topic in recent years that it is talked about by almost everybody and it extends to almost every sector.It has been applied into all manufacturing areas,seemingly posing a potential replacement of manufacturing methods.3D printing originates from a rapid prototyping technology to assist the manufacturing of new products for demonstration,and to test geometry and dimensions.By this method,there is no need to prepare patterns and dies by traditional methods,which can save a lot of cost and time.3D printing only makes prototypes,not real things for appplication;a prototype is mainly for shape analysis,for demonstration,or to be used for making a mould for producing a real casting.It is thought to befast because it avoids the preparation of die or tools which usually takes a lot of time.There are several 3D printing methods to make a prototype,such as fused deposition modelling,lamination object manufacturing,three dimensional printing,etc.

The casting process is actually very complicated,involving the making of a pattern manually or by machining,making the core and mould separately,which gives room for the application of 3D printing technologies in casting production.

If any inquiry about die casting,please send email to info@prodiecasting.com