Die casting is common use method in manufacturing.Failure of die casting tooling caused late delivery and cost increasing.Failure of tooling include following issues.

Weiheng Die Casting Always focus on quality of die casting parts and tooling.

- Metal Fatigue.The die casting bear high pressure of locking force,which cause deformation of inner part of die casting tooling after long time usage.Crack caused by thermal fatigue is common problem for die casting tooling.The issued is due to temperature changing inside tooling and mechanical impact make issue worse.In order to solve the problem,the material of tooling is very important.H13 steel is common use for die casting tooling core and cavity.

- Breakage.The breakage inside tooling can spread widely and cause big problem for tooling.The breakage will happen if tooling material properties can not meet requirement.Die casting operators are required to use proper die casting settings,which can slow down breakage and crack spread.Operators need to analyze strength on tooling and take special methods for special situation.

- Corrosion.The metal alloy are not very stable and often react with other material,which affect properties of metal alloy.Corrosion is main reason for failure of tooling.Common die casting alloy are zinc alloy,aluminum alloy and magnesium alloy,etc.These alloy react with other elements in certain circumstance.To slove this problem,nitridation is common method and good to improve hardness and abrasive resistance of inner surface of tooling.Also,the injection direction can be changed in order to direct impact upon cavity and core.

- Modern procedures of die casting tooling design

- Material organization.Get basic information of die casting parts that include of 2D and 3D file and customers requirements,etc.Fully understand technical data of drawings and function of die casting parts.

- Analysis of die casting parts.Die casting feasibility of parts.Material,structure,size tolerance,inner quality.Compare 2D drawing with 3D drawing to see if there are any difference.For unproper die casting formation and unnecessary structure,tooling engineer need to inform customers.The tooling design have to be good for formation and simplification of die casting parts as well as meet customer requirement.

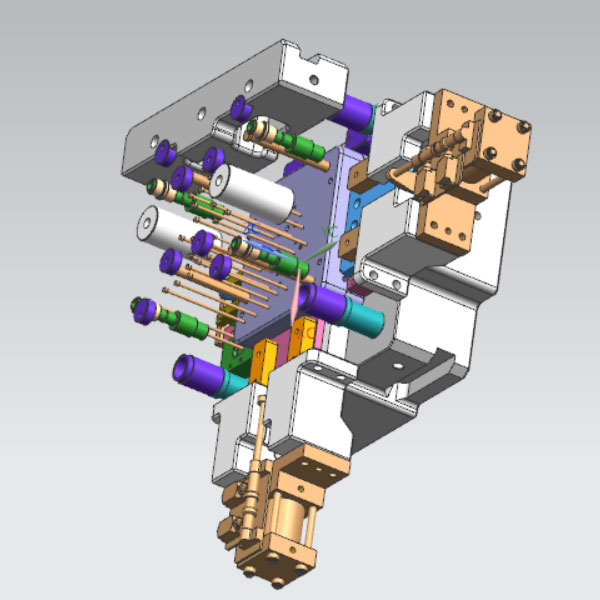

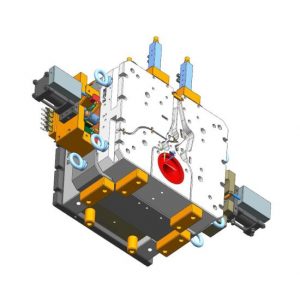

- Make sketch and assembly drawings of tooling.Constantly improve sketch and assembly drawings of tooling before finalization of tooling design.

Die casting is kind of process that integrate die casting machine and tooling with die casting alloy.Also,in addition to proper die casting process,die casting operators,engineers and tooling maintenance workers have to improve their skills.

- Set proper die casting parameters.Put injection speed,injection strength and temperature of melted alloy at lowest level.

- Apply coating inside tooling.Proper coating can extend life span of tooling

- Cooling down.In addition to cooling system built inside tooling,correct cooling method is necessary to improve die casting quality,efficiency and tooling life span.

All in all,die casting is excellent manufacturing process that can improve precision of product and get rid of defects of normal casting methods.

If any inquiry about die casting,please send email to info@prodiecasting.com