Die casting

High pressure die casting refer to method that melted alloy injected into cavities of tooling at very high pressure and speed.

The main feature of die casing is high speed and high pressure.1)melted alloy fill up by high pressure and formed at higher pressure.Normal pressure is 15-100MPa.2)Melted alloy fill up cavities of tooling at very high speed.Normally,it is 10 to 50 meters per seconds,even more than 80 meters per seconds sometimes.Therefore,it will take about 0.01 to 0.2 seconds to fill up cavities of tooling fully.Weiheng Die Casting always provide tooling in house service.

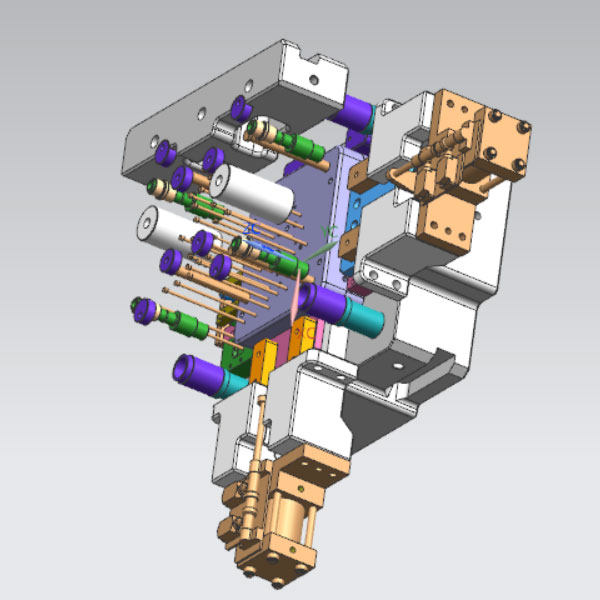

Tooling of Die Casting

Tooling is most important factor in manufacturing.The raw casting production will have problem if the design of tooling is not good.For example,the locking force apply on cavity and core is same but spure built on core,so the raw casting parts are stick to surface of core nevertheless cavity polished very well.Therefore,designer have to take all factors into consideration and familiar with die casting machine during make of tooling.

The melted alloy injected into cavity at very short time and high pressure.Therefore,the working condition of die casting tooling is very tough and inner temperature of tooling change quickly,which have negative effect of life span of tooling.The life span of tooling normally refer to life span when tooling are properly designed and used.

During manufacturing,there are three main factors which make tooling became non-workable.1)Crack due to metal fatigue.2)Broken.3)Etch

There are several factors that make tooling fail,such as high temperature,pre heat of tooling,casting released spray,Size of part match locking force or not,Composition of Fe in alloy,shape of casting,wall thickness etc.Also,other factors need to be considered,such as quality of alloy,design of tooling,heat treatment of tooling,polishing of cavity,etc.

During die casting,slight crack might be caused by temperature change from hot to cold over and over again.One crack become big,melted alloy flow into it,which make crack become more badly.Therefore,pre heating of tooling is necessary and make die casting manufacturing in certain inner temperature of tooling.

If any inquiry about die casting,please send email to info@prodiecasting.com