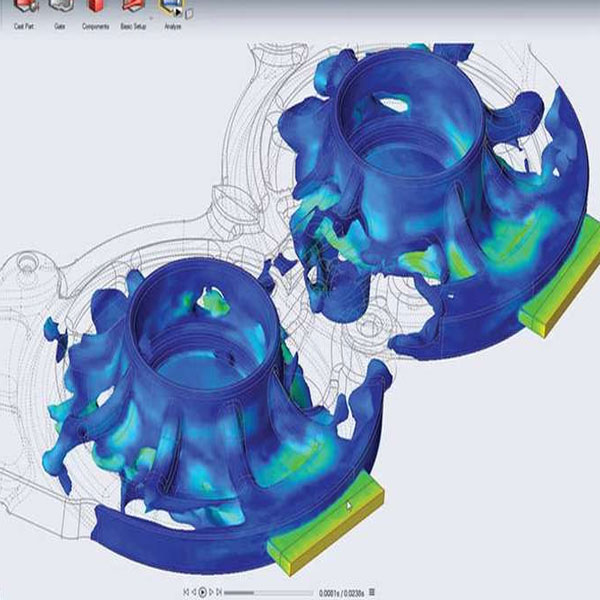

The die casting products have many defects shown on software.The main problems happened due to non-uniform wall thickness.The melted alloy did not fill up thicker wall area because melted alloy did not flow straightly via runners and injection speed slow down in such runners.Weiheng Die Casting Provide Professional One-Stop Die Casting Service.

By 3D flow software,we can find problem and improve tooling design.

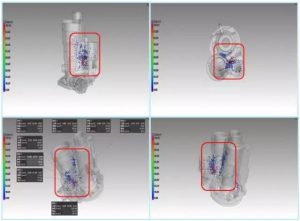

- Improve filling in thick area of die casting products.

- Change two runners into one runners to improve filling and aovid injection speed slow down.

We can check how melted alloy flow on software and see if there are problem of vent and filling,especailly for big and thick die casting products.

There are some important datas in 3D flow software.We can check these datas to see if tooling design are improved.We can also short filling time,improve die casting products life span and ventilation of tooling.

Software can show the result by comparision with several datas of toolings,which help tooling designer to check tooling totally.

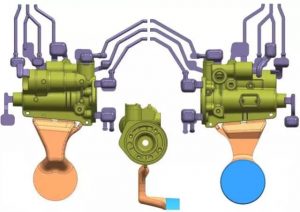

In the future,we would know how die casting parts form,at how long time and how much temperature by inputing tooling datas into 3D flow software.

If any inquiry about die casting,please send email to info@prodiecasting.com