Check our main product & service

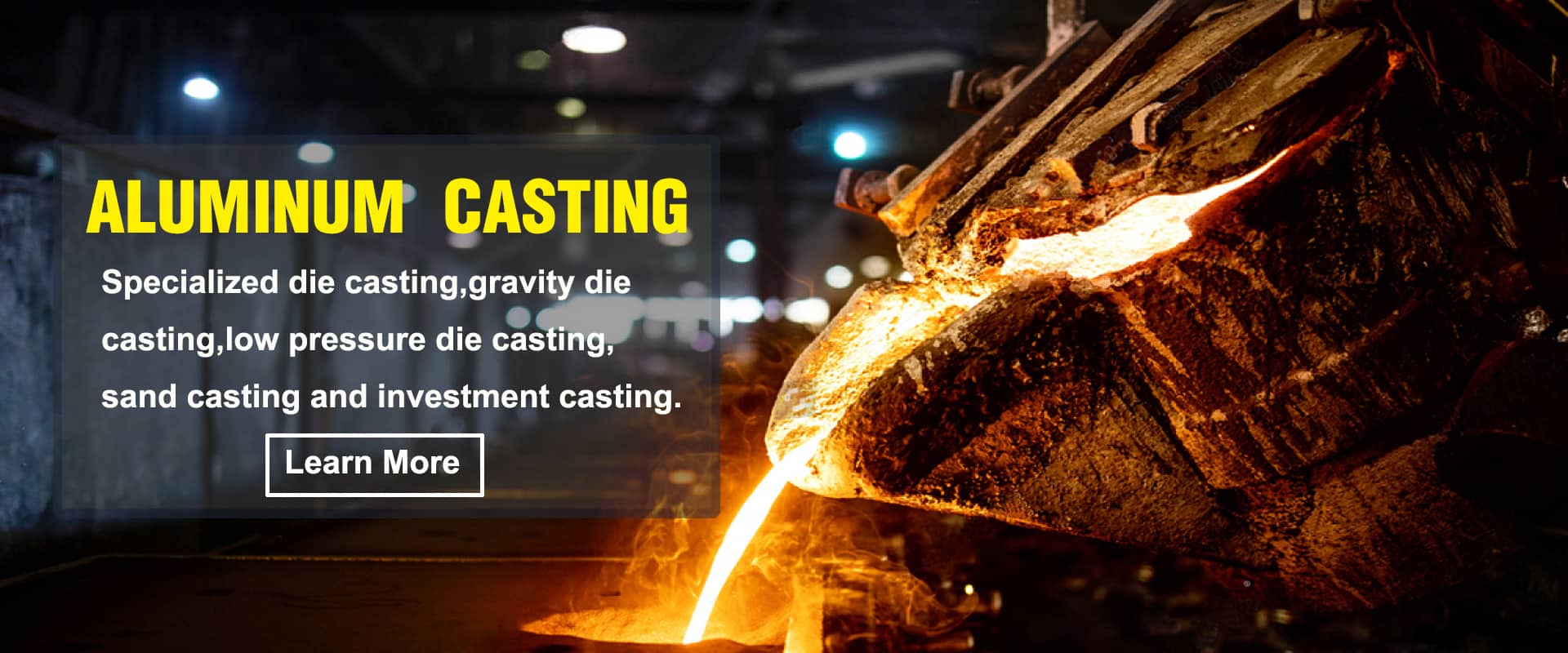

Aluminum Casting

As leading casting factory in China, we provide full range of aluminum casting service inclusive of high pressure die casting, gravity die casting, low pressure die casting, sand casting. Our aluminum casting parts can be 0.01kg to 100kg in complex or simple geometry.

Customers can come to us with their basic concept, samples or drawings, we will choose proper manufacturing processing and let them become final product they want.

We have in-house tooling design and making capability. Customers do not worry about high cost and low efficieny and non guaranteed delivery time caused by outsourcing tooling production provided by some casting suppliers.

We also provide precision machining and surface treatment in order to save production time and cost for our customers.

Sheet Metal Fabrication

In addition to aluminum casting, we also provide sheet metal fabrication for our customers. In this field, we are specialised in producing metal enclosure, metal cabinet, heavy duty metal cabinet, display panel and all kinds of metal structure parts, etc.

Our sheet metal fabrication include CNC bending, CNC punching, brushing, welding, sheet metal laser cutting, tube laser custing, powder coating, anodizing etc.

The customers can enjoy "drawing to parts" one-stop service in our factory. With our professional working team and excellent management, we are really pride on providing sheet metal fabrication at competitive price.

We also provide precision machining and surface treatment in order to save production time and cost for our customers.

We're aluminum casting, sheet metal fabrication

manufacturer and supplier

We, Cangzhou Weiheng Metal Products Co.,Ltd, was established in 2000 year. We are contract manufacturer that are specialised in aluminum casting and sheet metal fabrication in China.

Our company currently own 30000 square meters plant and above 200 experienced staff. Our main customers are mainly from Auotmotive industry, Lighting industry, Mechanical Equipment industry, Telecommunication industry etc.

What we do

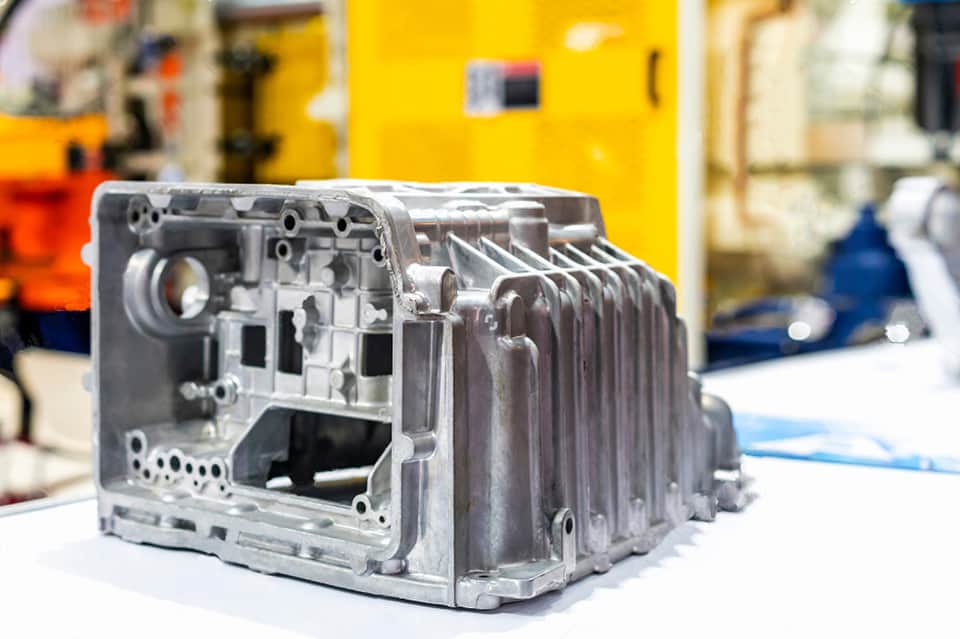

High Pressure Die Casting

Die casting manufacturing for aluminum alloy is the most common for the die casting process today because they can be used in wide range of industries.

We produce aluminum die casting parts via cold chamber die casting machine from 300 ton to 1250 ton.Our die casting machine are from yizumi and L.K group.

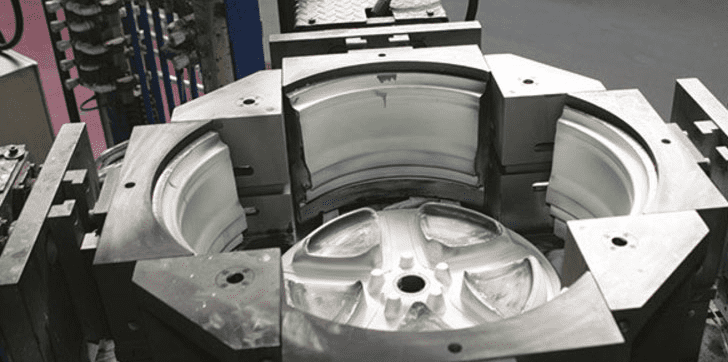

Gravity Die Casting

We provide extremely competitive aluminum gravity die casing service for our customers. Our production capacity for gravity die casting is ranged from few grams to 100-plus kilograms.Our tilt pour gravity casting machine can handle all of casting jobs in short run time and low cost.

Sheet Metal Fabrication

We do not only provide aluminum die casting service but also sheet metal fabrication. Many customers come to us with their design which include sheet metal parts so we decide to extend our business to sheet metal making to give customer much better service.

At present, we have full set of sheet metal fabrication equipment. Our service have bending roll forming deep drawing spinning shearing blanking punching laser cutting. We have no problem with quick lead time on high volume runs for sheet metal parts.

Tooling

Our in-house tooling capability provide our customer with best quality of molds. The tooling were designed by our professional engineers and made via experienced tooling worker and advanced tooling making equipment.

Good quality tooling can make jobs much easier and reduce the defects of final products. We put a lot of work and effort on making good tooling in order to produce products our customer really want and guarantee delivery time.

Precision Machining

Most of time, aluminum die casting parts need secondary machine to meet customers requirement. No matter how complex the parts are, our machining equipment and capability can fully accomplish best finishing of final products.

Our machining service mostly include multi-drilling multi-tapping milling boring turning grinding. Therefore, we are pretty sure that you can find everything for your design in our factory.

Surface Treatment

Good surface treatment can offer eye attractive finishing and corrosion resistance. Therefore, More and more customer pay attention to surface finishing. In weiheng, customers do not need to worry about surface finishing because we provide fully surface treatment.

We have plenty experience to deal with aluminum die casting parts surface. We can do polishing electroplating powder coating anodizing shot blasting. Come to us with your idea, we will offer professional service on your surface requirement.

Quality Control

We full operate according to iso 9001:2008. All of die casting parts will be tested and checked before packing and delivery. The advanced tools and technique we develop guarantee final parts quality without any problem.

We deeply know that quality control are foundation of whole die casting process. Our workers are obligated to provide parts with zero defect.

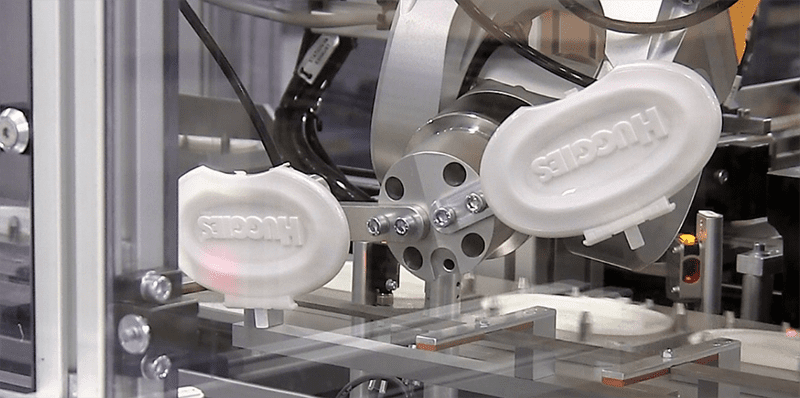

Custom Assembly

We can also provide special packaging or assemble product ready for use on customers production line. Our core assemly capacity is to utilize various of methods to make all of components assembled together.

Our semi and manual assembly line can fully meet all kinds of requirement and get job done in most efficient and cost effective way. We assure of good quality and high precision final product to our customers.

9 industries we served

LIGHTHING

AUTOMOTIVE

SURVEILLANCE CAMERA

APPLIANCES

TELECOMMUNICATION

SHEET METAL FABRICATION

MECHANICAL COMPONENTS

HYDRULIC COMPONENTS

FURNITURE PARTS

Why choose us

What our customers say about us

Ask us anything you want

Are you manufacturer?

Yes, we are aluminum casting and sheet metal fabrication manufacturer with over 20 years working experience.

Do your company make tooling in house?

Yes, we are specialised in tooling make and save money on tooling investment for our customers.

Do you provide drawing optimization?

Yes, we provide drawing optimization for free according to manufacturing feasibility.

Do you provide prototyping before volume production?

Whatever aluminum casting or sheet metal fabrication,we provide protyotyping as per customer requirement at reasonable price.

Do you have quality traceability system?

Yes, we use professional ERP and have traceability of the product history.