Aluminum alloy featured light weight,good strength and hardness,nice thermal properties.It can be used for many industries.The aesthetic finishing can be excellent after anodizing.However,for anodizing purpose,the main production method is to make aluminum parts by CNC machining.However,CNC is kind of complex process,which is quite expensive and time costly.Many material is wasted during CNC machining.

Al-Si,Al-Si-Cu,Al-Mg and Al-Si-Mg are four common die casting aluminum series.The Al-Mg series alloy is most suitable for anodizing.But the fluidity of Al-Mg alloy is poor,which cause die casting difficulty badly.To solve this issue,we put Mn into alloy to enhance fluidity maximumly.By testing in professional instrument,the fluidity can reach 91% of ADC12.It can be suitable for many kinds of die casting parts.Mn can also reduce soldering problem against cavities.Normally,Fe is the role to reduce soldering problem in common die casting aluminum like ADC12.But Fe affect anodizing finishing badly,so we replace Fe with Mn instead.

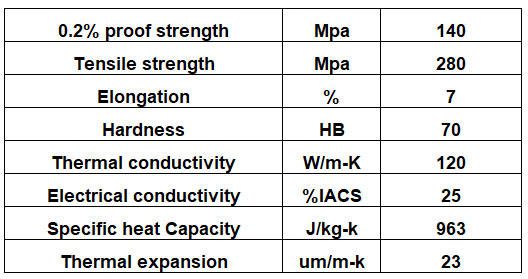

Once the fluidity issue was solved,we turned to mechanical strength requirement.Most of die casting parts have certain mechanical requirement.After adding Mn into Al-Mg,the tensile strength and yield strength can be 110Mpa and 210Mpa respectively.The hardness can only reach 40% of ADC12,which is not enough for most of die casting parts.After some testing,we found Zn can improve hardness very much as well as tensile and yield strength.Finally,Al-Mn-Mg-Zn alloy has following properties in chart.

By adding Sc,the hardness and other mechanical properties can be improved dramatically.However,it is not recommended in consideration of commercial purpose since Sc is far too expensive.

At tooling design stage,Al-Mn-Mg-Zn is quite different from ADC12.The sprue gate is much larger.The runner layout is more complex than ADC12 die casting parts.Overflows qty and size is different from ADC12 die casting.

By particular design of tooling,the turbulence of molten alloy can be minimized,which can reduce flow trace maximumly after anodizing.

The mold and molten alloy temperature need to be controlled strictly,otherwise the cracks will happen onto die casting parts.

By compare with anodized ADC12 die casting parts(left one in the photo),Al-Mn-Mg-Zn anodized die casting parts(right one in the photo) is more shiny and stylish and the anodizing finishing is more consistent.

The Al-Mn-Mg-Zn die casting parts can be hard coat anodizing as well.The below picture is hard coat anodizing finishing.The anodizing layer thickness is 45μm.

Please contact us if any inquiry for die casting parts.info@prodiecasting.com