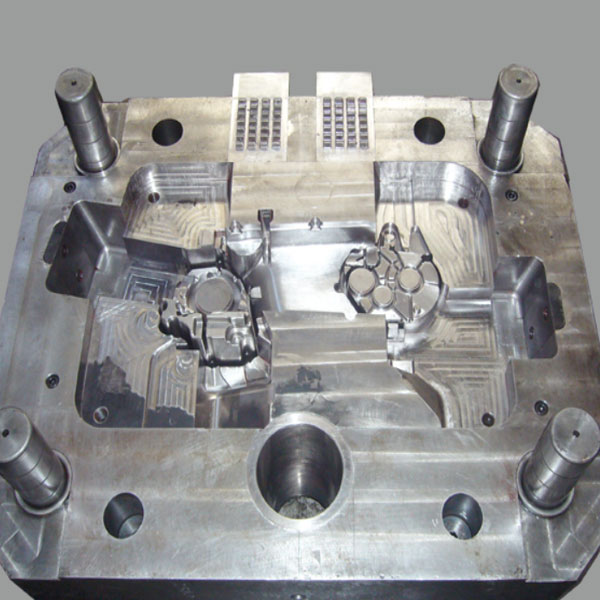

During die casting processing,core life span affected by high temperature melted alloy,release agent,cooling air and grip strength of casting.Core failure has caused most machine down during manufacturing.Therefore,research on core failure is useful to reduce machine down and improve manufacturing efficiency.Weiheng die casting is professional die casting supplier.

There are several common types of core failure,core deformation,sticking,core breakage etc.

Core breakage

Core breakage mainly happen to long length of core or core with sliders.Breakage mostly due to metal fatigue.

Core deformation

Most core failure are core deformation.The installation of core are vertical to the direction of melted alloy injected.The front of core suffer from high pressure of injection,therefore,the long core is easy to deform.When core deformation happen,the defect will happen to castings.

Core size change and sticking problem

Sticking problem happen to the tooling area where the melted alloy injected affect mostly.The release agent hardly adhere to the surface of core,so the melted alloy is easy to stick to the surface of core.

The solution for core failure

The lost cause by core failure are the sub-standard castings produced.For example,some hole formed by core has ununiform wall thickness due to deformation of core.

Firstly,the material hardness for core should be 44-48HRC.Sometimes,the hardness even reach to 50HRC for core.

To avoid sticking problem,there must be certain proportion of Fe in aluminum alloy beside spray of release agent onto mould.In addition to these two methods,PVC,CVD,PACVD to tooling surface is really helpful to improve anti-sticking,oxidation resistance and abrasive resistance for tooling.

By research,melted aluminum alloy corrode core material badly when angle of impact within 72-75 degree.

Tooling user must follow instruction of tooling usage.Dont hit core badly during cleaning.For some small core,the user need to prepare some spare parts in case of machine down.

To extend life span of tooling,we not only improve skill of user but also optimize the tooling design.Core is part that is easy to wear out,so proper maintenance is necessary to improve efficiency of tooling and avoid lost caused by core failure.

If any inquiry about die casting,please send email to info@prodiecasting.com